Edge AI in manufacturing allows you to perform predictive maintenance and quality control directly on the factory floor. It enables your machines to analyze sensor data instantly, detecting early signs of wear or defects. This real-time insight helps prevent costly equipment failures and guarantees high product quality. By minimizing delays and manual inspections, you can boost efficiency and reduce downtime. To discover how these innovations can transform your operations, explore further insights below.

Key Takeaways

- Edge AI enables real-time sensor data analysis for immediate predictive maintenance and quality control on the factory floor.

- It detects early machinery faults and defects, reducing downtime and ensuring consistent product quality.

- Localized processing minimizes latency, supporting faster decision-making and prompt corrective actions.

- Implementing Edge AI improves operational efficiency while lowering maintenance costs and preventing costly equipment failures.

- AI-powered vision systems on-site enhance defect detection accuracy and enable quick responses during manufacturing processes.

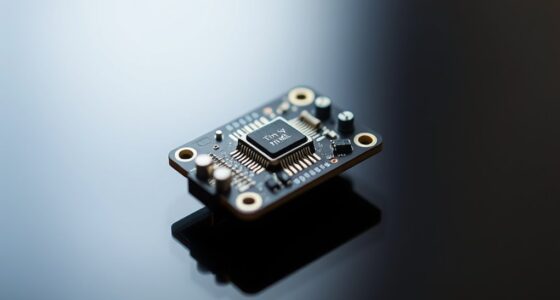

Edge AI is transforming manufacturing by enabling real-time data processing right on the factory floor. This shift allows you to analyze sensor data instantly, reducing dependence on distant servers and minimizing latency. instead of waiting for information to travel to the cloud and back, your machines can make immediate decisions, which boosts efficiency and minimizes downtime. When your equipment detects an anomaly, Edge AI can trigger alerts or even initiate corrective actions on the spot, preventing costly failures before they happen. This immediate responsiveness is a game-changer, giving you greater control over your production line and helping maintain consistent quality.

Predictive maintenance stands out as one of the most impactful applications of Edge AI in manufacturing. By continuously monitoring the health of your machinery through embedded sensors, Edge AI models can identify patterns indicating wear or malfunction. For example, vibrations, temperature shifts, or sound anomalies are analyzed instantly, so you can schedule maintenance proactively rather than reactively. This approach reduces unexpected breakdowns, cuts maintenance costs, and extends equipment lifespan. It also streamlines your workflow, ensuring that maintenance activities happen only when necessary, avoiding unnecessary downtime. As a result, you keep production running smoothly, with less disruption and more predictable schedules.

In addition to maintenance, Edge AI enhances quality control processes. Instead of relying solely on manual inspections or delayed quality checks, you can deploy AI-powered vision systems directly on the factory floor. These systems analyze products as they move along the assembly line, detecting defects or inconsistencies with high precision. Because the analysis occurs locally, you get immediate feedback, enabling you to reject faulty items before they reach the next stage or the customer. This real-time detection minimizes waste, improves product consistency, and accelerates your overall throughput. Furthermore, Edge AI systems can adapt to new defect patterns quickly, learning from ongoing production data to stay effective even as manufacturing conditions evolve.

Frequently Asked Questions

How Does Edge AI Differ From Traditional AI in Manufacturing?

Edge AI differs from traditional AI in manufacturing by processing data directly on local devices rather than relying on centralized servers. You get faster decision-making, reduced latency, and increased privacy since sensitive data stays on-site. With Edge AI, you can quickly detect issues or optimize processes in real-time, which minimizes downtime and improves quality. It’s more efficient, responsive, and better suited for environments where instant insights are critical.

What Are the Cost Implications of Implementing Edge AI Solutions?

Implementing edge AI can lower your costs over time by reducing reliance on centralized data centers and minimizing latency, which improves efficiency. While upfront investments in hardware and integration might seem high, they often lead to savings through decreased downtime, lower data transmission fees, and improved product quality. You’ll also benefit from faster decision-making and less need for extensive data storage, ultimately making your manufacturing process more cost-effective.

How Secure Is Data Processed Locally on Manufacturing Equipment?

You can feel confident that data processed locally on manufacturing equipment is quite secure, as it stays within your system without needing to travel over networks vulnerable to cyber threats. Edge AI minimizes exposure to external attacks, and your security measures—like encryption, access controls, and regular updates—further protect sensitive information. While no system is entirely risk-free, local processing markedly reduces the likelihood of data breaches.

Can Edge AI Integrate With Existing Manufacturing Systems Seamlessly?

Yes, edge AI can integrate seamlessly with your existing manufacturing systems. It’s designed to work alongside current equipment, often through standard protocols and APIs, minimizing disruptions. You’ll find that it enhances your operations by providing real-time insights without requiring major overhauls. With proper planning and collaboration with vendors, you can guarantee smooth integration, boosting efficiency and maintaining your existing workflows effectively.

What Are the Best Practices for Maintaining Edge AI Devices in Factories?

To keep your edge AI devices running smoothly, regularly update their software and firmware to patch vulnerabilities and improve performance. Guarantee proper cooling and protection from dust, moisture, and physical damage. Schedule routine maintenance checks and monitor device performance through dashboards. Train your staff on troubleshooting and best practices. By staying proactive, you minimize downtime, extend device lifespan, and ensure your factory’s AI systems operate efficiently and reliably.

Conclusion

While some might worry that implementing Edge AI is complex or costly, the reality is it offers quick ROI by reducing downtime and defects. You don’t need to overhaul your entire system overnight—start small, integrate gradually, and see immediate benefits. Embracing Edge AI empowers you to stay competitive, improve quality, and streamline operations. Don’t let hesitation hold you back—taking the leap today can lead to a smarter, more efficient manufacturing future.