Generative design transforms manufacturing by helping you create innovative, optimized components faster and more efficiently. It explores countless design options based on your constraints and goals, reducing material use, weight, and costs. This technology enables you to develop complex, lightweight structures that were once impossible with traditional methods, especially in aerospace and automotive industries. It complements additive manufacturing, allowing rapid prototyping and customization. Stay tuned to discover how this breakthrough reshapes industrial processes and product development.

Key Takeaways

- Enables rapid development of optimized, lightweight components for aerospace and automotive industries.

- Facilitates complex, innovative part geometries that improve performance and reduce material use.

- Supports customization and rapid prototyping tailored to specific customer or application needs.

- Integrates seamlessly with additive manufacturing for producing intricate, high-strength parts.

- Accelerates product development cycles, reducing costs and time-to-market.

Generative design is revolutionizing manufacturing by enabling companies to create optimized, innovative components faster and more efficiently. Instead of relying solely on traditional design methods, you now have access to advanced algorithms that explore countless design possibilities based on your specific constraints and goals. This technology analyzes factors like material use, strength, weight, and cost, allowing you to identify the most effective design solutions without extensive manual trial and error. This approach, supported by automation, helps reduce development time markedly, bringing products to market quicker while maintaining high standards of quality.

When you utilize generative design in manufacturing, you gain the ability to craft complex, lightweight structures that were previously impossible to produce with conventional techniques. For example, in aerospace and automotive industries, where reducing weight is vital, you can generate parts that maintain strength but drastically cut material usage. This not only improves fuel efficiency but also decreases overall production costs. By automating the exploration of innovative geometries, you can push the boundaries of traditional design, leading to parts that are both functional and aesthetically advanced. The software considers numerous parameters, such as load paths and material properties, to optimize each component for its intended purpose.

Another major advantage lies in the customization potential generative design offers. You can tailor components specifically for individual applications or customer needs without starting from scratch each time. This flexibility allows you to adapt designs quickly in response to changing market demands or new technological advancements. Furthermore, generative design helps identify design redundancies and inefficiencies early in the process, enabling you to eliminate unnecessary features and streamline manufacturing workflows. This results in more sustainable production practices, as less material waste is generated, and energy consumption is reduced.

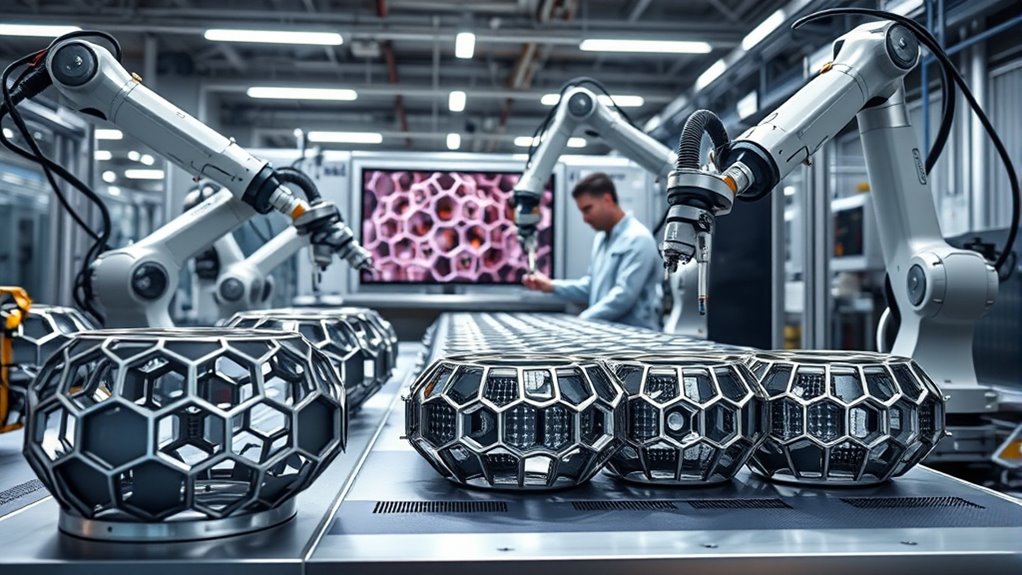

Integrating generative design with additive manufacturing amplifies its benefits, as complex geometries produced through generative algorithms can often only be realized with 3D printing technologies. You can produce parts with intricate internal structures that optimize strength and weight while maintaining ease of assembly. This synergy opens doors to innovative product concepts and rapid prototyping, allowing you to test and iterate designs quickly. As a result, your development cycle becomes more agile, and you can respond swiftly to evolving customer requirements or market trends.

Frequently Asked Questions

How Does Generative Design Impact Manufacturing Supply Chain Logistics?

Generative design streamlines your manufacturing supply chain by creating optimized parts that reduce material use and production time. It enables you to quickly develop innovative, lightweight components, which decrease shipping costs and inventory needs. The precise designs also improve product quality and durability, minimizing returns. Overall, it helps you respond faster to market demands, cut costs, and make your supply chain more agile and efficient.

What Are the Cost Differences Between Traditional and Generative Design Processes?

You’ll find that generative design can reduce costs by up to 20% compared to traditional methods. This is because it optimizes material usage, minimizes waste, and shortens design cycles. While initial investments in software and training may be higher, the long-term savings on materials, manufacturing time, and product development often outweigh these costs. Overall, generative design offers a more efficient, cost-effective approach for modern manufacturing.

Can Generative Design Be Applied to Small-Scale Manufacturing?

Yes, you can apply generative design to small-scale manufacturing. It allows you to optimize parts for better performance and material efficiency, even with limited production runs. You’ll find it especially useful for creating customized components or prototypes quickly. While it may require initial investment in software and expertise, the benefits of lightweight, innovative designs often outweigh the costs, making it a smart choice for small-scale projects.

How Does Generative Design Influence Product Lifecycle and Recyclability?

Generative design greatly boosts your product’s lifecycle and recyclability by creating optimized, lightweight structures that last longer and use less material. You’ll find that it fosters flexible fabrication and facilitates future recycling, reducing waste. By incorporating sustainable solutions from the start, you’re designing more durable, eco-friendly products that align with modern environmental expectations, ultimately saving resources and supporting smarter, more sustainable manufacturing practices.

What Are the Cybersecurity Concerns Related to Generative Design Data?

You should be aware that generative design data faces cybersecurity risks like hacking, data theft, and unauthorized access. These vulnerabilities can compromise sensitive design files and intellectual property. To safeguard your data, implement strong encryption, access controls, and regular security audits. Staying vigilant helps prevent cyber threats and ensures your innovative designs remain secure throughout the development process.

Conclusion

By now, you’ve seen how generative design transforms manufacturing processes, making them more efficient, innovative, and sustainable. It empowers you to create complex, optimized parts that were once impossible to conceive. As you embrace this technology, ask yourself: are you ready to lead the future of manufacturing, or will you let this revolutionary tool pass you by? The choice is yours—will you harness the full potential of generative design?